The type of AC or DC motor used in a locomotive train engine depends on the technology available, and technical advantages. And it also depends on the cost of running the train. I will also discuss the reason for using the AC or DC motor in the train engine.

The contents of this post are as follows.

Which motor is used in a locomotive train engine

Long back, electric engine locomotives were using DC motors. Then around the year 2000 in India, we started using 3-phase AC motors with GTO-based converter inverter control technology.

Nowadays, a Three-phase AC induction motor is used in the electric locomotive train engine with IGBT-type converters and inverters.

This kind of AC induction motor is specially designed for traction applications. So, we call this type of motor a Traction motor.

These traction motors are optimized for high energy efficiency, train vibrations, environments with moisture and salt, and better power and weight ratio.

Many times these motors are custom-built depending on the requirements of the train engine.

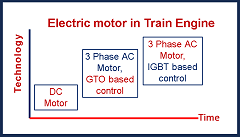

Technology growth

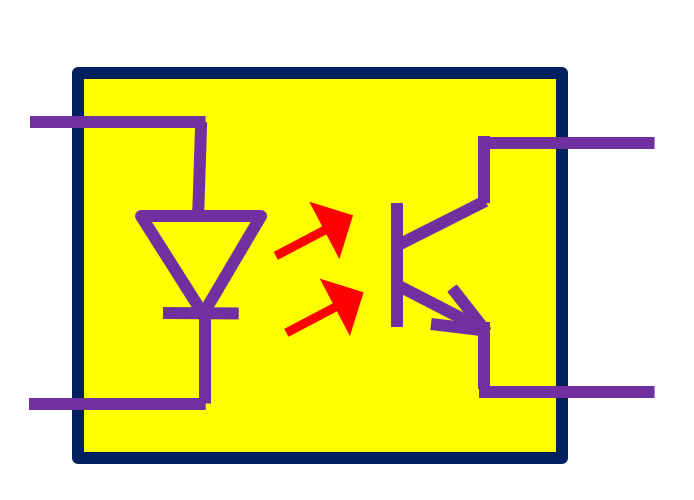

Refer to Figure 1. Earlier DC motors were used as GTO or IGBT technology was not available. Then GTO-based technology was available for 3-phase AC motors. So 3 3-phase motor with a GTO-type converter was found better.

With the advent of the IGBT system, converters and inverters use the IGBT-type system.

I will discuss the advantages and reasons for the use of the AC induction motor with IGBT technology in the electric locomotive train engine in detail in this post.

Why use AC motor in train engine with IGBT – advantage

Now we use VVVF type control. VVVF means the variable voltage and variable frequency.

We control both the voltage and frequency of the output voltage applied to the motor in the VVVF technology system. VFD means variable frequency drive. But we use the VVVF system nowadays.

The use of an AC motor along with IGBT based VVVF system in the train engine has many advantages as follows:

- Better speed control

- Better acceleration control

- Better power factor

- Fewer harmonics

- Less maintenance

- More effective regeneration braking

- More power saving

- Better torque control

- Better slip between wheel and rail control

- Better adhesive limit

- Better power distribution or axil control

- Low running cost

Now I will discuss some of the above advantages in more detail.

Speed and acceleration control

3-phase AC motor with IGBT type converter and inverter, along with VVFD control provides

- Better speed control

- Better acceleration control

Power factor and harmonics

3-phase AC motor and IGBT type VVFD also provides

- Unity power factor

- Very fewer harmonics

This provides less disturbance to the AC power supply system.

Maintenance of AC motor used in a train engine

This AC type of induction motor in the train engine also has very little maintenance. It is much easier to maintain a 3-phase squirrel case induction motor compared to a DC motor. As AC motor has no mechanical contacts like brushes in DC motor.

Low maintenance of the motor reduces the downtime for the maintenance of the train engine.

Less downtime of the train engine is equivalent to better utility time and hence less cost.

Weight of the AC motor and performance

AC motors are lighter than DC motors for the same power.

The IGBT-type VVVF control with 3 3-phase AC induction motor gives better performance for a given weight and volume, compared to a DC motor.

Better regenerative braking in the AC motor in train engine

The cost of the electricity consumed is one of the major running costs in the train system.

The regenerating braking system provides better savings in electricity.

What is regenerative braking in the train?

The mass of the train is very high. So the train stores too much kinetic energy as per formula E= 1/2 mv2. This energy is stored in the full train, not only in the engine.

As and when we want to stop the train, we convert this kinetic energy to electrical energy.

The AC motor operates in a generation range and the 3-phase inverter becomes a rectifier.

Thus electrical energy regenerated from the kinetic energy is sent back to the 3-phase transmission system.

We call this concept regenerative braking. This way considerable saving in electricity is possible, especially when there are frequent stops in the train journey.

This kind of regeneration of energy during braking operation (stopping the train) is much more efficient in the case of an AC motor being used in a train engine.

Overall regenerative braking helps as follows

- Less wear and tear on the brake system

- More energy savings

- fast money payback period.

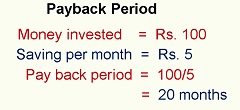

Economics of money payback period

Figure 2 explains the Payback period in brief. If the money invested is 100 and the saving per month is Rs. 5. Then the payback period is 100/5 = 20 months.

The AC motor has a very good payback period due to electricity savings. A low payback period is one of the most important reasons to use AC motors in electric train locomotives. This also encourages the railways to replace old technology with AC motors.

Tractive effort and adhesive level

AC motor with IGBT control system provides better tractive effort and higher adhesive level.

I will try to explain this complicated topic now.

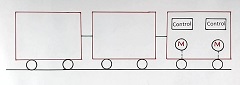

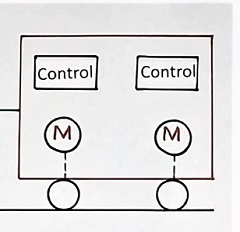

Please refer to Figure 3. A locomotive engine is on the right side of the figure. The engine has control, motors and wheels along with the body of the engine.

To explain easily, I give an example of a normal car. A car has tyres over the wheels and the road is rough. So the car can move forward due to the rough surface of the road and the tyre on the wheel.

A wheel without a tyre and a sliding surface of the road will make it very difficult to move a car. It is nearly impossible to move a car. if its wheels are in wet mud, then it is more difficult to move the car even with the full accelerator.

The train wheel does not have tyres. The rail (in place of the road) is also not rough. So it will be difficult to move the train forward, even if we apply force. The wheel will slip and the train may not move.

That is where the concept of friction ( a part of the adhesion) between wheel and rail comes in. Adhesion ( a type of friction) is required very much to move any vehicle or engine.

The concept of adhesion in a train engine

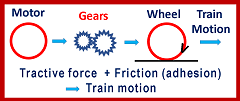

Please refer to figure 4 to understand the concept of adhesion. The friction and the weight of the locomotive at the wheel contact point decide the adhesion. The tractive force (engine power) and adhesion are responsible for the train motion.

AC motor control can provide better traction when used in a train engine. The formulas for the tractive effort and adhesion are as follows.

Tractive force + Friction (Adhesion) = Train motion

Tractive effort = Weight x Adhesion

Adhesion = Coefficient of friction x Adhesion variable

The adhesion variable is the ability of the engine ( locomotive) to convert available friction into usable friction at the wheel and rail interface.

Why weight of the train engine is very high

As per the above formula, a heavy body of the locomotive ( weight) also increases adhesion. That is why the mass of the locomotive is very high.

Adhesion limit

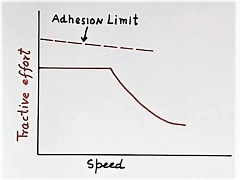

IGBT and AC motors can control tractive effort in a better way in a train engine. The tractive effort should be more but less than the adhesive limit. This is possible easily in the AC motor. Refer to Figure 5.

If adhesion is not proper and braking effort is more than the adhesive limit then the train will slip during the application of the brake and the train will not stop.

Wheel slip slide control during braking or acceleration of the train

Further, another advantage of using the AC motor in a train engine is that the AC motor along with IGBT has better slip control ( between rail and wheels).

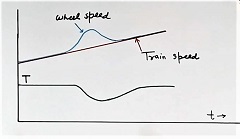

Now, refer to Figure 6 to understand this very interesting topic. See carefully, I have shown 2 different plots for train speed and wheel speed.

The speed of the wheel and train should be the same. If the wheel speed is more than the train speed, then the wheel will slip as shown in the middle of the graph at the top.

The control system measures the slip continuously. Then the control reduces the torque of the motor ( see the middle of the” “T” in Figure 6) to reduce the wheel speed in case of a slip in the wheel in a train engine.

After the speed of the wheel and train becomes equal (slip zero) as shown, the torque level becomes normal again. This is difficult with a DC motor.

So as discussed above, the AC motor along with IGBT has better tractive effort and adhesion with the help of slip-slide control as per Figure 6.

Continue to read which motor ( AC or DC) is used in a train engine locomotive and why.

Different motor power to different axil of the train engine

Further AC motors along with IGBT can provide different power to different axil or bogies. It is to get a better adhesion level and effort.

Now, refer to Figure 7 to understand this axil power control in a train engine.

The locomotive has many motors and different controls to control the many wheels.

All the wheels of the locomotive do not have equal power load and weight. (we will not discuss the reason for this). So different wheels require different power. This axil power control can be done with IGBT, VVFD and AC motors.

So we can get better axil power control when an AC motor is used in a train engine. As we use many converter inverters in the VVVF system, then we can adjust different power references in different converter inverters of the VVFD system.

Note: a simple interesting real-life example

If the tyre of a car slips on the wet mud, then power should be reduced and weight is increased as per the above theory.

However, in practice, we always do the opposite (including myself). We always increase the power and reduce the weight of the car by asking all passengers to come out.

In fact, no passenger will sit inside the car to help and cooperate. We think (including me) that help means coming out of the car and also remaining safe. (This is my opinion only).

I hope that you enjoyed to the learn about the topic “Which motor (AC, DC) is used in the locomotive or train engines and why”.

Extra knowledge as per experience

Generally, 2 sets of VVFD systems including the motor are used in a single train engine in a typical train.

Each VVVF system has half the power of total power of the train engine.

Many times while travelling on the train, I found that the train stops a long time in a station on the ground because the engine has a problem. I was wondering why the train engine always fails at the station only, but not in between the journey.

But the fact is that the engine can fail any time between journeys. However only one system may have a problem out of the two VVVF (variable voltage variable frequency) systems. So the train still can move but with half the engine power.

Then, the engine is replaced with a good engine as and when possible at the next stop at a station.

In fact, whenever we need a more reliable system, we almost always use more than one system to provide redundancy.

Further, to learn more detail on why AC motor watch AC or DC motor in the locomotive

I hope that you enjoyed the article on “which motor (AC or DC) is used in a train engine and why”.

Also read about ” what is metal oxide varistor, and how to use it“

Moreover, read another article – AC or dc which is more dangerous.

Further, read “Why use neutral in induction motor”.

Also read, How high-speed train can go so fast.

Keep learning and read why power factor improvement.

Further read about Ungrounded electrical system.

If you like the article then subscribe YouTube channel.

About the author – G K Agrawal B.Sc and B.Tech (from HBTU Kanpur), Retd. Sr DGM Design (BHEL), the inventor of patents, has lifelong industry experience in the electrical and electronics design field of R&D. He worked for BHEL. He shares his experience and knowledge on blogs and YouTube. Read the profile here.

I know tһis if off topic Ƅut I’m looking into starting mу own weblog аnd wаs curiouѕ what all

is required to get set up? I’m assuming haᴠing

a bⅼog likе yours would сost a pretty penny?

I’m not very web smart so I’m not 100% positive.

Any recommendations or advice woսld be ɡreatly apprecіated.

Aρpreciate it

I am not expert.