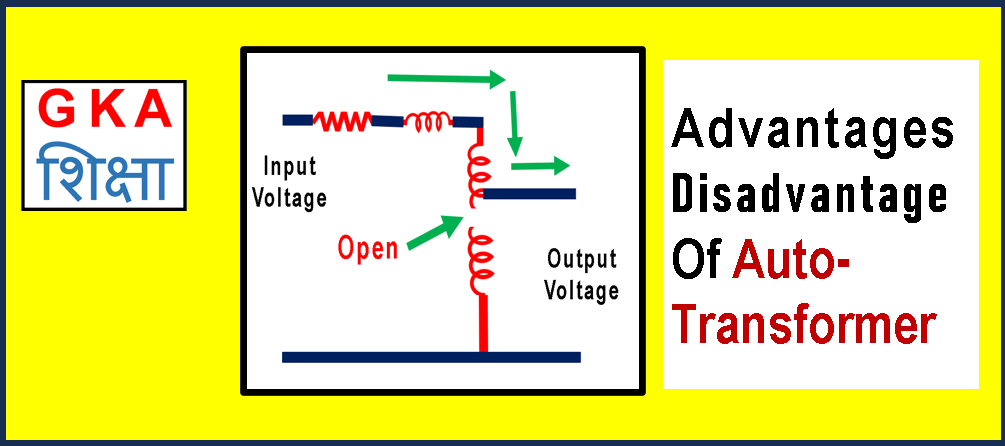

In this article, I explain the advantages and disadvantages of the Autotransformer (Auto-transformer). I will also explain the disadvantage of the autotransformer during fault at the output and also due to damage in the wire of the winding.

The autotransformer has many advantages and disadvantages over the isolation-type transformer.

The main advantages of the autotransformer are its small size and low cost, and the main disadvantages are no isolation and problems during fault.

The content of the article is as follows:

Advantages of the autotransformer

There are the following advantages of the autotransformer:

1 – Smaller size – The size of the autotransformer is small as it has only one winding. Further, the size of the core also will become smaller.

2 – Less weight – The weight of the autotransformer is less as it has only one winding and also due to the small core size.

The size of the core of the autotransformer is less due to less opening required for less copper in the windings. However, there may not be any saving in the cross-section area of the core as it depends on the input voltage, which remains the same.

3 – Low cost – The cost of the autotransformer is very less due to savings in copper and core material, as it has only one copper winding and a small core size. Further time for the manufacturing also will be less. So manpower cost also less.

In fact, reducing the size and weight of the transformer has cascading advantages in cost like less raw material requirement, less store space, less packing cost, less transport cost, etc. All these reduce the financial requirement.

4 – Less voltage drop and voltage fluctuation due to load change

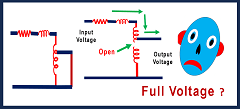

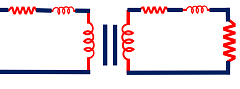

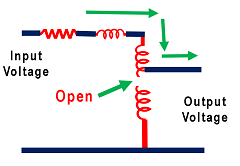

Figure 1 shows the electrical diagram of the isolation-type transformer. It has two windings. Both the windings have some impedance. So whenever current flows in the load, then there will be a voltage drop in both the windings. So voltage regulation is poor due to more voltage drops.

Figure 2 shows the electrical diagram with the load of the autotransformer. As an autotransformer has only one winding, it has impedance in only one winding. So whenever electrical current flows, there will be a voltage drop due to load in only one winding impedance. So voltage variation is less, or we say voltage regulation is better.

So there will be less voltage drop and voltage fluctuation due to changes in load at the output.

5 – Variable output voltage

If the autotransformer is Variac type, then we can provide the continuously variable voltage to the load for testing purposes or for any other application.

Note: Even if we say that an autotransformer has one winding, many times this one winding actually consists of two windings connected in series. And one of them will have a thick copper wire to take care of the high current of the load. This is especially applicable if the ratio of the voltage of output and input is less.

Disadvantages of the autotransformer

We discussed above the advantages of the autotransformer, now we will discuss the disadvantages of the autotransformer. There are the following disadvantages of the autotransformer

1 – No isolation between the primary and secondary winding

The main disadvantage of the autotransformer is that it does not have electrical isolation between primary and secondary windings.

2 – More current during fault

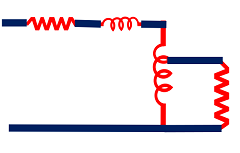

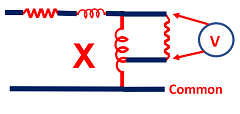

Figure 3 shows the electrical diagram of the autotransformer during the fault. In this circuit, the output is directly connected to the common. Now during a such fault, the current is limited by the impedance of the transformer.

As an autotransformer has only one winding impedance, so, the impedance is less ( in an Isolation type transformer both primary and secondary windings will have impedance).

Due to less impedance, the current flow during an output short circuit will be more. Hence more short circuit current problems.

So this single winding impedance in the autotransformer has the advantages of less voltage variation but disadvantages of high current during a fault in the autotransformer.

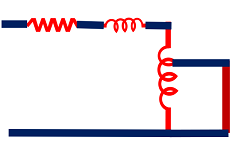

3 – Full voltage at the output during wire break in the winding

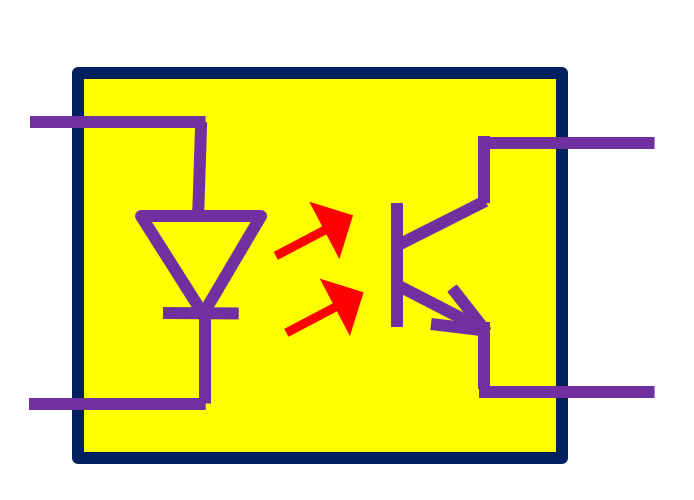

Now figure 4 shows the electrical circuit during the opening of the wire in the winding. The wire of the winding is open at some place (below the load point).

You can see that full voltage appears at the output during wire damage. Now the load connected to the output will get high voltage and will get damaged.

4 – Not economical for less voltage ratio

The autotransformer is not economical for less voltage ratio between output and input. The size and cost of the autotransformer will increase with less output-to-input voltage ratio (fixed ratio type).

Conclusion

So autotransformer has many advantages and disadvantages over isolation-type transformer. The major advantages are its small size, low cost and weight, and less voltage drop. The major disadvantages are its operation during fault at the output and also in the winding. We also call it auto-transformer. The variac version of the autotransformer can give continuous variable output voltage.

Extra knowledge as per experience

The applications of the autotransformer require special attention to avoid the danger of high voltage at the output. The load should be connected between the output terminal and the common terminal only.

If we connect the load between the output and noncommon terminal, then high voltage may come at the output at the lower voltage setting.

Do it yourself (DIY)

Just measure the voltage between the output and the main terminal as per the circuit connection in Figure 5, and you will know the problem.

For further knowledge watch the video given below:

Further, read Open circuit CT transformer use.

Keep learning about the application of autotransformers.

Also, read what is the potential transformer.

Continue reading for more learning about The difference between CT and PT transformers.

Further, read the applications of the diode.

Also, read “How to test transformer at home with multimeter”.

I hope that you enjoyed the article on the advantages and disadvantages of the autotransformer.

If so, then subscribe to my YouTube channel.

About the author – G K Agrawal B.Sc and B.Tech (from HBTU Kanpur), Retd. Sr DGM Design (BHEL), the inventor of patents, has lifelong industry experience in the electrical and electronics design field of R&D. He worked for BHEL. He shares his experience and knowledge on blogs and YouTube. Read the profile here.

Very good information.